Today, the biggest trend in tooling systems is automation.

"A few years ago, I anticipated the arrival of a labor shortage," explains Lisa Goulet, president of Aiguisatek. "So we started making our entire process technology six or seven years ago."

Aiguisatek offers the most complete solution for cutting tool maintenance in the industry. Their philosophy is to provide customers with services that ensure optimum tool quality, profitability, reliability and durability - essential for any manufacturer. They are constantly seeking solutions tailored to their customers' needs, and are committed to providing a personalized and valuable service in the fields of sharpening and equipment. This includes having reliable, high-tech machines in their own workshop to provide the best possible service. This means automation.

People always worry about jobs disappearing because of automation, but it seems rather that automation is filling roles for which it is difficult to find employees. It also improves productivity, consistency and creates more attractive jobs for jobseekers.

If Ms. Goulet had foreseen the labor shortage, she could never have predicted the pandemic. At the height of the COVID restrictions, Aiguisatek suffered a loss of 30 %. Not all its manufacturing customers were considered essential, and therefore not all its customers were operational. Their losses would probably have been greater had they not had automated solutions.

"As our staff had to stay at home, we faced the challenge of maintaining low production with two people, which we nevertheless managed thanks to automated production with Vollmer grinding technology," said Ms. Goulet.

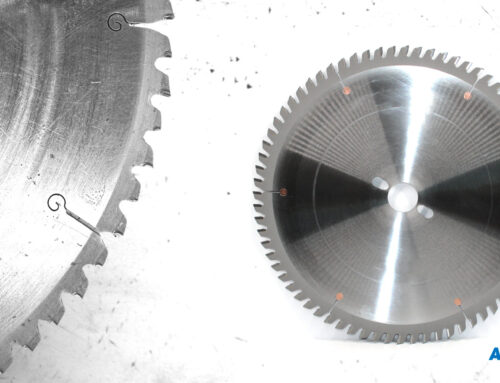

The Vollmer CHD 270 grinding machine with ND 250 loader enabled unmanned manufacture and machining of carbide circular saw blades around the clock. The loading carriages of the ND 250 robotic system can accommodate up to 450 saw blades with a maximum load of 1.5 tons. And soon they'll have another machine that can run 24/7, as they invest in a new PDC machine.

It's only logical that if the joinery industry is moving towards automation, companies like Aiguisatek that count joiners among their customers should do the same.

"We're looking to automate everything we can in the future," said Goulet. "This drives up tooling performance. We want to optimize tooling for our customers."

"We're looking to automate everything we can in the future," said Goulet. "This drives up tooling performance. We want to optimize tooling for our customers."

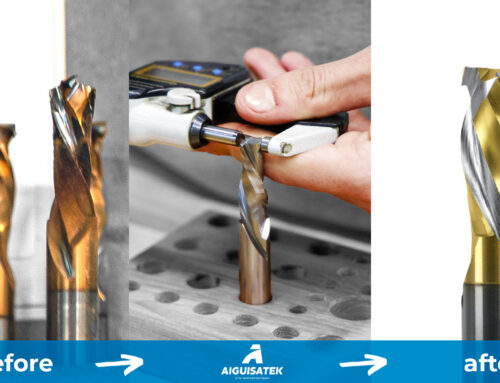

Optimization is essential, and it's also the biggest challenge. When I asked if people knew what they were doing wrong, the answer was a resounding "no". Jonathan Riberdy, VP, full of stories of companies making costly mistakes.

"I was doing a site visit for a countertop manufacturer, and I was walking along the production line. I was listening to a saw blade, and I knew something was wrong," said Riberdy. "So, I asked him if he had read all the information on the blade because what he had there - it wasn't even cutting."

The customer was hesitant because the recommended blade was 40 % more expensive than his current model. He didn't realize that the increased cost on the invoice would save him tons in additional production costs. When you consider what it costs in lost production time, repairs and labor, it adds up quickly.

"We did the math and changing the blades on this machine saved them about 15,000 $ per year per blade," explains Mr. Riberdy. "And this machine alone had four blades."

He compared such a mistake to putting cheap tires on a sports car. Investing in better-quality blades for cutting systems can make all the difference. Almost all routers and saw blades sold by Aiguisatek are Canadian-made. This has been the case ever since Ms. Goulet's father founded the company 35 years ago.

"You can't always see the value on your invoice, but when you see the results, there's no doubt," said Riberdy. "It's not just about the blade, it's about the technical expertise and solutions we provide."

Source: https://www.lemondedubois.com/loutil-juste/