Sharpening losses for the company

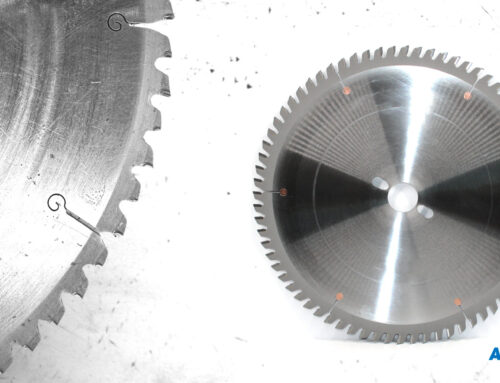

At the height of the restrictions imposed by the COVID-19 pandemic, many companies faced unprecedented challenges. Aiguisatek, specialized in the manufacture of circular saws, was no exception, recording significant losses of the order of 30 %. Faced with this crisis, the company had to react quickly to ensure its survival. This is where automation came into play, proving to be a major asset in these uncertain times.

Automation arrives at Aiguisatek

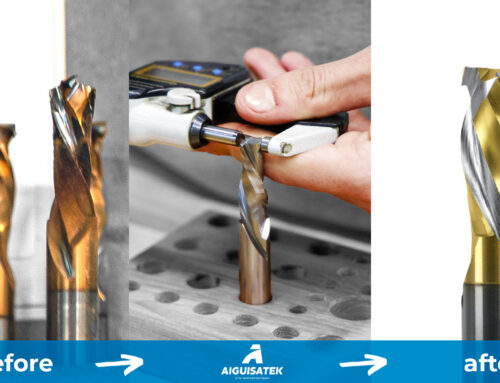

By implementing automated systems, Aiguisatek was able to optimize its production process, increase efficiency and reduce costs. The decision to adopt 24-hour production was a major turning point for the company. Thanks to this initiative, it was able to meet the growing demand for circular saws, even when pandemic-related restrictions were at their height.

Automation enabled Aiguisatek to minimize the risks associated with the spread of the virus among workers, as fewer personnel were needed on the production site. In addition, it helped maintain consistent product quality, which is essential for retaining customer loyalty despite the challenges encountered. By reducing dependence on human labor, the company was also able to cope with unpredictable market fluctuations with greater agility.

Conclusion

Beyond the pandemic, investing in automation has proved to be a long-term strategic decision for Aiguisatek. Not only has it enabled the company to overcome immediate challenges, it has also opened up new opportunities for growth and expansion. By strengthening its competitiveness in the marketplace, the company is now better positioned to thrive in an ever-changing world, where efficiency and innovation are key elements of commercial success. Thus, despite the difficulties encountered during the pandemic, Aiguisatek was able to turn a crisis into an opportunity, thanks to automation and its ability to adapt.

Find out more about the Delson company, click here.

Source: https://afdicq.ca/