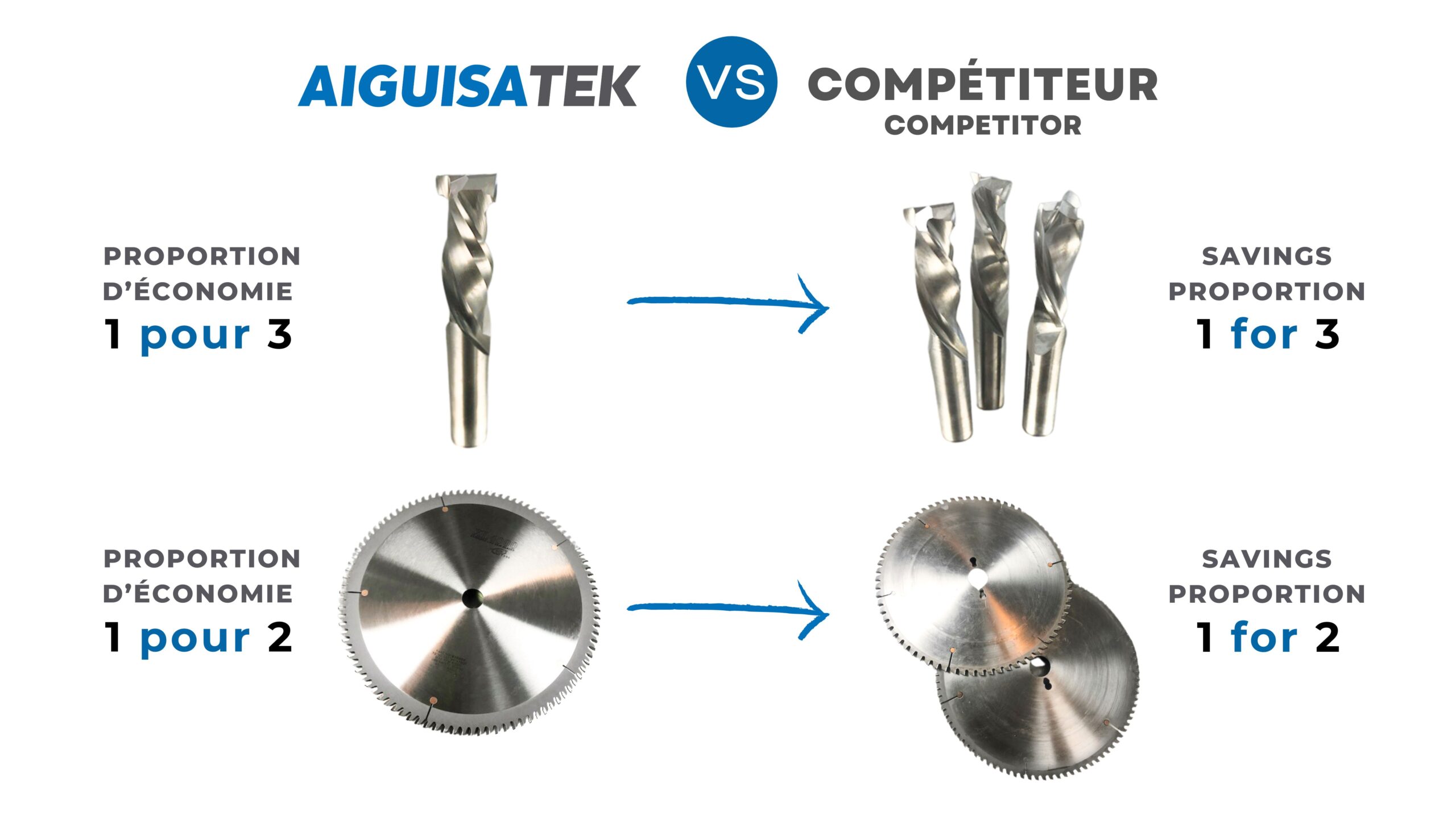

Aiguisatek stands out from the competition thanks to its expertise in sharpening and remanufacturing. How do we do it? With its ability to remove as little material as possible from each tool. This principle, which requires unparalleled control and expertise, is carried out by their specialized technicians.

To illustrate our service, here is a concrete example:

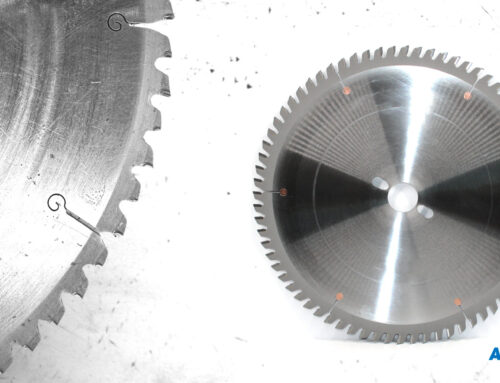

According to market standards, regardless of the material removed during sharpening, an industrial blade will be sharpened approximately 12 times. This requires less time and less checking, as each blade is treated in the same way.

Compared to Aiguisatek's service, our pre-sharpening verification and control system makes sure that the wear zone is clearly identified, ensuring that sharpening only takes place there. This allows us to remove as little as possible from the tool to recover the original cutting edge. With this principle, we can achieve up to 20 sharpenings on an industrial saw blade.

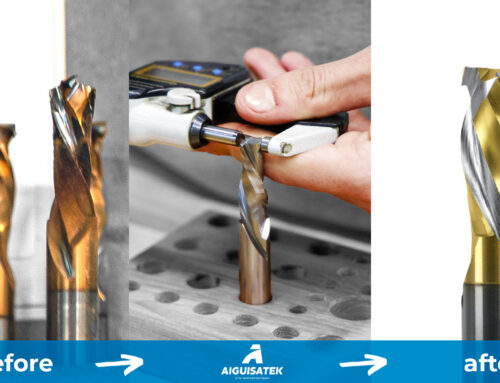

For compression-type bits, Aiguisatek offers 6 sharpenings compared to others where we only offer 3. This same technique is used for all the tools we receive.

Services offered by Aiguisatek

- Pre-sharpening check system

- Precise detection of the area to be improved

- Only the minimum will be removed from the tool to give it a longer service life.

If you too would like to save 30% to 40% on your annual tool sharpening and remanufacturing bills, contact us today!