Aiguisatek - Focus on customers

HOW WALTER MACHINES GIVE AIGUISATEK AND ITS CUSTOMERS LONGER TOOL LIFE 300 %

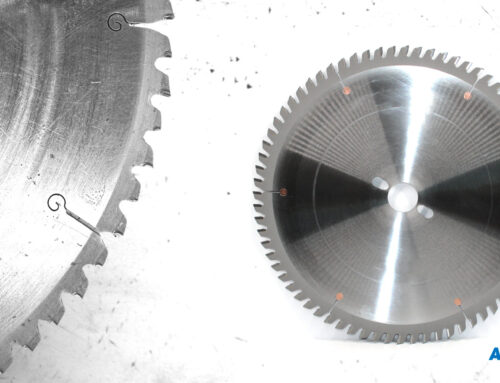

In 1986, just south of Montreal, Mario Dion and Conrad Goulet founded Aiguisatek. Over the decades, the company has expanded its expertise and reach. Today (and thanks in part to a partnership with UNITED GRINDING North America), the company handles solid carbide and PCD tools, maximizing tool life for the woodworking industry like few others.

Before partnering with UNITED GRINDING North America, they aspired to be one of the best grinding service centers in Canada. With their WALTER equipment and its 2-in-1 grinding/erosion capability, this dream has become a reality.

"The tools we service on our WALTER tool grinder give our woodworking customers up to 300 % of extra tool life," said Jonathan Riberdy, vice president of Aiguisatek. "Annually, they save between 30 % and 60 % on their total bill, which is huge."

The defining moment in Aiguisatek's history

Before founding Aiguisatek, Conrad Goulet worked for years with a Canadian tool manufacturer. "His philosophy throughout his career was to find ways to give customers the highest possible productivity," says Lisa Goulet, Conrad's daughter and President of Aiguisatek.

When Conrad died suddenly in 2010, Lisa and Jonathan, Lisa's son and Conrad's grandson, had to make a decision: continue on their current career path and sell the company, or retrain in machining careers to keep the business in the family.

They chose the second option, and aimed to grow the business while never losing sight of Conrad's original philosophy. Today, having added square footage, state-of-the-art technology and extra capacity, their Quebec customers know that few stores do as much for tool life as Aiguisatek.

And when the company was introduced to UNITED GRINDING North America and WALTER tool grinders, this attribute was further reinforced.

How Aiguisatek discovered UNITED GRINDING North America

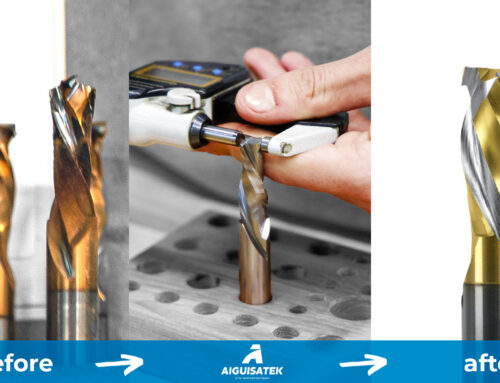

In 2017, Aiguisatek was a victim of delivery times and the quality of their subcontractors. "One of the main factors that drove us to acquire our first WALTER machine was simply to bring this work back in-house," said Riberdy. "That was our only goal, but once we saw what the WALTER could do, once we understood the geometry of the tools, that's when we realized how much more we could do. Now, every tool we pick up goes back to working like a new tool."

Before the purchase, Goulet and Riberdy were hesitant due to their lack of experience and the size of the investment. They knew that UNITED GRINDING's equipment was the best choice, but they also looked at other options. But once they got to Germany and GrindTec, they were fully convinced.

"We had a goal of becoming a large cutting tool service center, and seeing the WALTER up close-and talking to other WALTER customers-showed us that the machine would allow us to grow and realize that service center vision," said Riberdy. "We were starting from scratch, but the machine would open doors for us. We both knew we'd be filling it and producing at full capacity in a year or two."

Training with the UNITED GRINDING North America team

Riberdy learned the ins and outs of WALTER and its software, TOOL STUDIO, at the TOOL STUDIO Basics training course in Virginia. "The first day, I thought, oh my, this is much more complicated than I thought. Day two was much better, and day three was easy. This software is where we've made big improvements on tool life and on the tool itself. For me and the guys who use it every day, it's honestly pretty easy. You just have to learn the functionality."

"I remember pulling out a blueprint at the training center in Virginia," said Riberdy. "It's the only tool we need to make, but it's a complicated tool. My trainer looked at it and said, 'Okay, it's not easy. But we're going to solve it.'"

Once training for this carbide tool was complete, training for PCD tools came soon after. "This was intentional on UNITED GRINDING's part," said Riberdy. "They knew it would be difficult for me to learn both applications at the same time, so we staggered them. I got used to grinding, then I was trained in erosion. By that time, the trainer who was handling PCD had left, so they actually brought in someone from Germany to train us." Riberdy says that today, Aiguisatek's WALTER machines run 10 to 16 hours a day, with 60 % of the time devoted to resharpening and 40 % to erosion.

The Value of UNITED GRINDING North America

Goulet and Riberdy may have hesitated before their first tool grinder purchase, but in the end they found a partner who shares their philosophy of quality.

"Things were uncertain after my father passed away, but the beacon we kept seeing said QUALITY, QUALITY, QUALITY," said Goulet. "We tell our customers, 'Don't just look at the price. Look at the results and you'll see it's a good choice.'"

"We now have our second WALTER machine. We're doing business with UNITED GRINDING again because the value has been proven. We know how productive the machine has made us."

Riberdy said it best: "You think you're saving a lot of money by buying a cheaper machine, but then it gives you headaches every day. It always breaks down, you're always on the phone, you spend five figures to fix it. In the end, you save nothing."

"At Aiguisatek, we don't seem to have the best initial ROI. But in the long run, we do. That's the advantage of quality, reliability and precision over time. We see UNITED GRINDING the same way: the best return on investment in the end."

Aiguisatek's promising future

The company is in the midst of a three-year plan to double its business. "We're looking to expand further west into Canada and do business in the U.S. as well," said Riberdy. The company will continue to work with partners like UNITED GRINDING North America who enable them to deliver on their promise of good-as-new tool service.

So if, like Aiguisatek, you need a partner who understands your vision and has the precision to make it a reality, partner with UNITED GRINDING North America. Our machines and people combine to deliver unmatched value and peace of mind - before, during and after the purchase.