The global pandemic has had an impact on businesses around the world, but for Aiguisatek, the impact has been compounded by strict local regulations in the province of Quebec that have virtually shut down manufacturing in the region. Fortunately for the Delson, Quebec-based company, its investment in a Vollmer CHD 270 8-axis circular saw blade sharpening machine with Vollmer ND250 automation station enabled the company to maintain unattended production throughout the pandemic.

Founded in 1986 by Mario Dion and Conrad Goulet, the 15-employee company designs, manufactures, sharpens and maintains cutting tools, circular saw blades, milling cutters, cutting blocks, profiling tools and special tools for the wood, metal, paper, plastic and composite industries. Like many companies, Aiguisatek began with a single machine in a garage, the founders concentrating mainly on saw blades and cutters. Aiguisatek got off to a promising start with the combination of highly qualified engineers and a Vollmer Akemat grinding center.

Since its inception, the company has grown exponentially and expanded its product and service offering - something that has been supported over the years by six Vollmer Akemat circular saw blade sharpening machines. In 2011, the daughter and grandson of company founder Conrad Goulet took over the business. Lisa Goulet and Jonathan Riberdy have since moved the company forward by relocating to a new 14,000 sq. ft. facility, investing heavily in new machine tools and implementing a diversification strategy into PCD cutting tools.

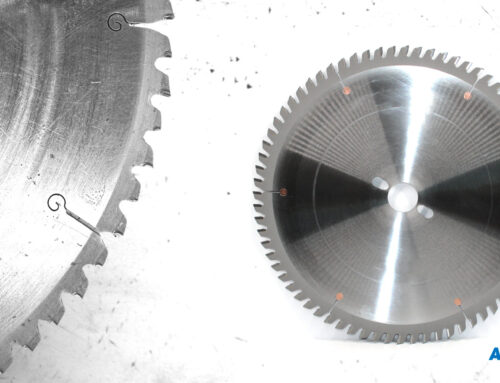

In 2013, the company realized that its saw blade service department relied on aging Akemat machines that were labor-intensive to meet its weekly demand of 350 to 400 saw blades. This was compounded by the growing requirement for 80, 100 and 125 millimeter division saws that had to be processed manually.

New-generation equipment

The solution was a Vollmer CP200 4-axis CNC face and top saw blade sharpening machine. Commenting on this, Jonathan Riberdy states:

"Demand for dividing saws was increasing, and each blade was taking up to 15 minutes to process manually. By purchasing the Vollmer CP200, we reduced production time to three to four minutes. This eased the pressure and capacity demands on both the Akemat machines and the staff. The Vollmer CP200 has also given us much more - it has improved our resharpening and service quality; it has improved our throughput; and the machine's versatility has enabled us to produce blades with more complex geometries.

"In 2013, we had several saw blades that were causing problems. These saws had to be subcontracted to be resharpened. Just one example was a 10-inch-diameter saw blade with 130-tooth fine teeth. The CP200 enabled us to bring difficult blades back in-house and eliminate subcontracting costs and dependence on third-party suppliers. The CNC control unit and software on the CP200 also made setup and programming extremely fast and efficient."

Solving growth challenges

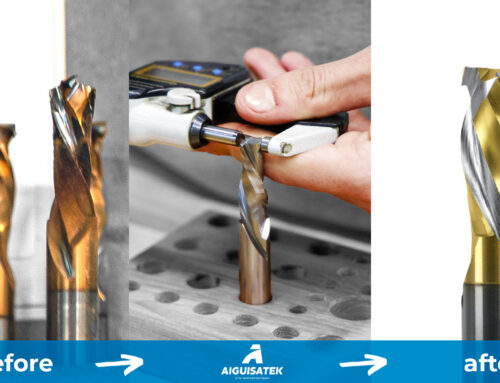

In 2015, Aiguisatek moved into PCD cutting tools, expanding its offering and market share with existing customers as well as winning new ones. Since this diversification, Aiguisatek has grown by 25 % annually, expanding beyond its local customer base to support customers in the Quebec and Ontario regions. Of course, such aggressive growth not only in PCD tools but also in TCT saw blades required additional investment. So, in 2019, the company acquired a Vollmer CHD270 8-axis face and top saw tooth sharpening machine with Vollmer ND250 automation solution as part of a $1.5 million investment program.

Alluding to this growth, Aiguisatek president Lisa Goulet declares:

"PCD tools have been a driver of change for us and have accelerated growth. In a short space of time, our product mix is now 35 % PCD and 65 % carbide tooling. At the same time, our TCT sawblade department has grown by an average of 15 % a year, and we now serve over 1,000 sawblades a week. We wouldn't have sustained this growth without the investment in the Vollmer CHD270 and ND250, and almost 90 % of our customer base is in the woodworking industry. We now have three employees delivering/collecting saws and tools daily to manufacturers ranging from cabinets and furniture to windows, doors and the construction industry."

With production requirements increasing from 350 to 1,000 blades per week, the Vollmer CHD270 was a necessity. Commenting on this, Riberdy says: "As production increased, we had aging machines and two experienced but aging operators running seven machines non-stop every day. This bottleneck was creating a stressful environment for the operators, whose considerable experience was keeping inconsistent quality at a manageable level. We knew we needed a solution, and the CHD270 provided it."

Increased production

The CHD270 installed in 2019 can handle saw blades from 3.15 to 33 inches in diameter, while the ND250 four-axis double-clamp automation cell has five carriages to accommodate up to 450 saw blades or a maximum load of 1,500 kg. This has been a game-changer for Aiguisatek, a growing company in a stagnant market.

Recalling the situation, Riberdy continues:

"The saw department changed overnight. We went from two operators running seven machines non-stop to one operator working on the CHD270, CP200 and one or two Akemat machines. With the Vollmer CHD270, our operator can spend two hours loading and unloading around 150 saws, then setting up the machine to run 24 hours a day unattended - giving the operator the time and ability to work on other machines."

"The Vollmer CHD270 processes one saw at a time, so it's not as fast as two men running seven machines simultaneously all day. However, we used to have two men working 10 hours a day to produce 150 saws on seven machines - now the Vollmer CHD270+ND250 runs 24 hours a day, six days a week, giving us the same weekly production capacity from an unattended machine as we had with two men and seven machines. Instead of running seven machines simultaneously for 10 hours, the CHD270 achieves the same daily output by running all night unattended. Not only does the Vollmer compensate for time and output during the week, it also runs unattended over the weekend. Now we run around 10 to 15 % of our blades through the Akemat machines for a few hours a day, with the CHD270 doing most of the blades."

Exceeding expectations

Aiguisatek has built up an enviable reputation for service, quality, consistency and innovation, and Vollmer has played a central role in supporting it.

"The Vollmer CHD270 immediately improved the quality and consistency of our saw blades. With cycle probing and automatic wheel dressing, the repeatable quality really surprised us. This was a huge difference compared to our previous machines. By combining the stability and rigidity of the CHD270 with its cycle calibration and automation, the quality is outstanding," says Riberdy.

Like the CP200, the CHD270 has a user-friendly interface that simplifies programming with almost unlimited tooth geometry possibilities. As Riberdy states, "Our price point may be a little higher than our competitors, but we offer quantifiable savings with test reports. Our expert engineers will consult with customers on applications and material types to maximize performance, accuracy and reduce costs. The ability to easily create a variety of geometries with unsurpassed quality on the CP200 and CHD270 supports this service."

By creating test reports for customers, Aiguisatek can track the life cycle of saw blades from new to the last resharpening before blade replacement. Compared to its competitors, Aiguisatek can resharpen blades up to 20-25 times before replacement, whereas competitors can only achieve 10-12 resharpenings before costly blade replacement. Aiguisatek saw blades can achieve up to 50 % of superior tool life, and can increase cutting meters by more than 30 % per resharpening. This is due to the combination of expert on-site engineers and production processes on the CHD270 and CP200.

"With Vollmers, we know exactly what we're removing from each point every time we do a resharpening. There are no inconsistencies, and this gives the blades a much longer life. For new customers who question our price point, we show them the Vollmer machines their blades are made on - and that fills them with confidence in our quality," says Riberdy.

Impact of the pandemic

For Aiguisatek, the pandemic was a painful period that saw some customers go into liquidation, a factor compounded by the pandemic's market conditions and regional legislation that restricted trade to "essential manufacturing businesses" only. Commenting on this, Goulet says: "At Aiguisatek, we had challenges like all businesses. At the height of the restrictions, our business was down to just 30 %s. The challenge for us was to meet this low level of production without staff. Our staff weren't at work due to social distancing regulations, and Jonathan and I ran the business between us."

Jokingly, she concludes, "If it wasn't for the Vollmer CHD270+ND250, Jonathan would have had to work over 100 hours a week in the field to get the saw blades out for our customers! It's situations like this that highlight the benefits of automation and investing in quality machinery. Looking ahead, we're pleased to report that we're back to pre-COVID business levels last year, and as of October, our annual growth rate of 25 % is back on track."